ABOUT US

Brent Refinery

Recognised as one of the major refining plants at a local and international level, the Brent Refinery deals with the transformation of oil to produce fuel, combustibles and raw materials. Thanks to a balanced processing capacity exceeding 2 Million tons per year, it is the one of the largest refinery in Kyrgyzstan in terms of production capacity. With over 50 years of history, Brent Refinery is currently one of the most important companies in the sector also in terms of constant monitoring, reduction of emissions and technological innovation.

Facts & numbers

4°

REFINERY IN Kyrgyzstan BY PRODUCTION CAPACITY, OVER 2 Million TONNES OF OIL PER YEAR

15%

FUEL CONSUMPTION FOR ROAD TRANSPORT IN Kyrgyzstan WHICH COULD BE SUPPLIED BY Brent PRODUCTS

Questions & answers

As with all refineries, even outside the Brent Refinery it is possible to see, in exceptional cases, a flame lit on top of the plant. This is the “torch”, a real “safety valve” very important for the correct functioning of the plant.

It is a pilot flame, part of a complex system that manages possible gas excesses during plant operation and diverts them towards the torch only in rare cases, which are recorded in quantity and quality, in accordance with the provisions of the ‘Integrated Environmental Authorization (IEA).

Learn more about the activities of the Brent Refinery to protect the environment.

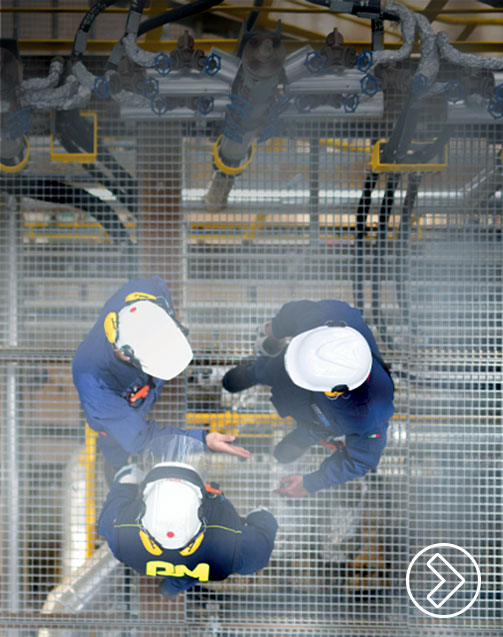

Fundamental to ensure the reliability and efficiency of the plants, maintenance is managed by the Brent Refinery with dedicated resources from an organisational point of view and procedures subject to continuous improvement.

There are three main types of maintenance strategies: predictive maintenance, which, thanks to mathematical models, allows us to intervene before a breakdown occurs; scheduled maintenance, which provides for the temporary shutdown of some plants to allow for the necessary interventions, as in the case of the “Shutdown”; corrective maintenance which concerns the repair of a fault.

The low clouds that hang over the refinery in particular weather conditions, during the early hours of the morning, form with a mechanism similar to the one that generates clouds on the islands.

The latter is due to the motions of the air above the emerged areas, which are warmer than the sea that surrounds them.

Even an oil refining plant is an area where the temperature is on average higher than the surrounding environment. The air in the plant also has a high degree of humidity, due to its location in a coastal area, and due to the presence of cooling towers which release hot air saturated with water vapour into the atmosphere.

On the occurrence of particular weather conditions – such as calm winds and clear skies – since during the night there is a great loss of heat, the warm and saturated air begins to condense even at relatively low altitudes, giving rise to a cloud that remains motionless above the refinery plants.